CNC Sauna, Easy Tool Changes, Projects, Firmware Updates

Happy Thursday Everyone!

We took an unexpectedly long hiatus from the weekly update there. I think I just needed a break from the sprint to get the kickstarter orders shipped.

Generally we’ve got lots of exciting news to share.

Firmware Updates:

I’ve been working on a pretty big firmware change.

Historically the way that the Maslow firmware has worked is that we’ve taken our code and used a gcode interpreter to convert that gcode into the correct XYZ movements for the CNC router to follow. We have then taken those XYZ movements and used them to drive the lengths of the belts.

This works well, but it means that all of our acceleration planning and feed rate limits are in done in XYZ coordinates. You can see this reflected in the Maslows settings where we have tunable parameters for XY and Z.

This doesn’t quite match up with reality. What we actually have is a 5 axis machine where each belt has its own max feed rate and acceleration.

Firmware version 1.08 adds that change so now we are going directly from gcode to ABCD (the four belt axis) and Z coordinates. This lets us better do acceleration and max feed rate planning in a way which better aligns with reality.

The full capabilities of each arm and the limitations of how fast the machine is capable of moving in any direction are taken into account when planning moves.

For most users the difference shouldn’t be that noticeable. The main reason for making this change was that we were finding that for some frame sizes and some gcode files it was possible to command the machine to move faster than it was physically capable of moving which would result in an error. Using all of the information in our calculations should fix that issue.

Firmware Version 1.09 builds on the changes in 1.08 and has been much more thoroughly tested.

This week we found and fixed a bug with the "Z-stop" setting which defines the lower limit of how low the z-axis could go. In switching from XYZ coordinates to ABCDZ coordinates I forgot to update the correct index for the which axis should be saved and loaded.

Excitingly this week we also got a pause button which I found super useful to pause long cuts to empty the dust collector:

And I also added a new tab which gives real time current readouts for how much current each motor is drawing. I added this for debugging purposes, but I found it so enjoyable to watch that I figured I would share it.

As always, give it a try and let us know what you think.

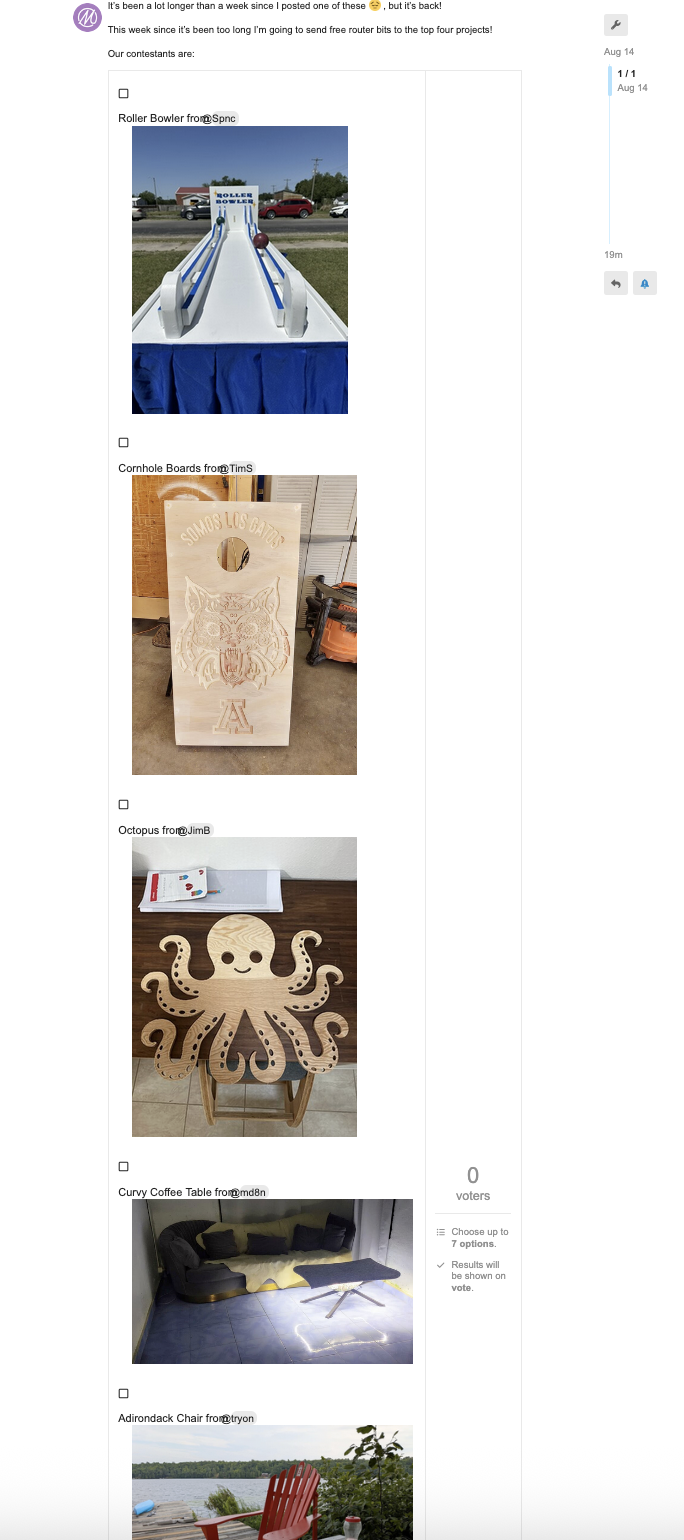

Projects of the Week(s):

Since it’s been a little while since we had a project of the week we’re going to be sending out router bits to the top four finishers this week so nobody misses out.

You can check them all out and vote for your favorite in the forums here!

CNC Sauna Build:

I started building Maslow because I wanted to be able to cut big things, cheaply, with limited work space. So that’s what I’ve been doing! I am working on a CNC cut sauna trailer.

The outside will be covered in corrugated roofing, the corrugations aren’t shown here because right now Abundance cant handle rendering them all 😁

I think that the very best way to improve a tool is to use it so that’s what I’ve been doing this week. I started working on a CNC cut sauna trailer.

The project is entirely designed in Abundance, gcode generated in Abundance, and cut with Maslow so it has been a great way to test the whole pipeline and make lots of improvements.

I started out by cutting four sheets of these ring parts:

It went pretty smoothly although I was really pushing it with my sheet alignment here:

I then assembled the cut parts into rings. Each ring double stacked so that the joints in one layer won’t line up with the joints in the next layer:

It was very satisfying putting these together. I wanted to tackle a project that I couldn’t build by hand, and I absolutely couldn’t have cut all these wiggly bits so that they would line up just right by hand.

The black ring will hold a big plexyglass dome for light.

One issue I ran into is that my design called for some recessed T-nuts to attach the rings to the floor of the sauna. They were supposed to be pocket cuts, but currently Abundance can only generate gcode which cuts all the way through. I though this would be fine, but it ended up leaving way to little wood to be structural so I’ll need to come up with another solution. It was fun to see that it’s possible to cut things that thin though.

For the long straight bits I decided to experiment with cutting them such that they share an edge with the next part, that way only half as much cutting needs to take place.

That went OK, but somewhat predictably I had a hard time getting the parts to not break free and become damaged during the cutting process. These parts will be hidden in the walls so they don’t need to be perfect, but I would like to find a way to get better results if I am going to try this again.

I have another big project which is time sensitive coming up so it might be a little while before I get to finish the sauna, but it feels so good to be putting real hours into a project, and it’s the best possible kind of testing.

Easy Tool Changes:

One last thing that I’ve been enjoying is this replacement for the stock dewalt collet. This one has a hex nut shape.

That’s important because it means that you can use a ratcheting wrench to make it much quicker and easier to change out the router bit with the limited space that we have available.